Table of Contents:

- How to Grow Cannabis 101: An Introduction to Cultivation

- Cannabis Greenhouse vs. Indoor Grow

- Minimizing Indoor Grow Costs

- How to Maximize Cannabis Yields

- Cannabis Greenhouse Construction Process

- Cannabis Cultivation Equipment

- Planning a Cannabis Cultivation Facility

- The Unique Challenges of Cannabis Cultivation

- VPD Dehumidification & Cannabis Cultivation

- Light and PAR

- Cannabis Irrigation

- Top 20 Cannabis Growing Questions – FAQ

- Glossary of Terms: Cannabis and Hemp Extraction

- Industry Resources

Light and PAR

How to optimize light transmission for your cannabis greenhouse

If you want to build a sustainable cannabis greenhouse, you need to design a facility that ensures optimal lighting conditions to maximize your crop yield. While typical greenhouse growers focus on getting as much natural daylight as possible to avoid the costs of artificial light sources, cannabis growers should know that more sunlight doesn’t always mean a higher yield.

There are many factors involved in determining appropriate lighting conditions for cannabis growing—from understanding PAR measurements and how it changes throughout the year, to choosing the right supplementary lighting that saves costs and maximizes production.

You’ll also need to leverage a deep understanding of greenhouse lighting and shading materials to ensure your cannabis crops are growing in a controlled, optimized environment.

In this chapter of the Ultimate Guide to Cannabis Cultivation, we’ll be diving into the critical lighting factors every grower should consider when designing a cannabis facility.

Table of Contents:

2. Sunlight and the Light Spectrum

4. HPS VS LED

What is PAR, PPFD, and DLI?

Developing an understanding of how light is received by plants and how to utilize variables of light intensity are crucial when it comes to preparing an ideal environment for your cannabis crops to thrive and survive sustainably.

As a cannabis greenhouse grower, you’ll need to be familiar with these three measurements: PAR, PPFD, and DLI.

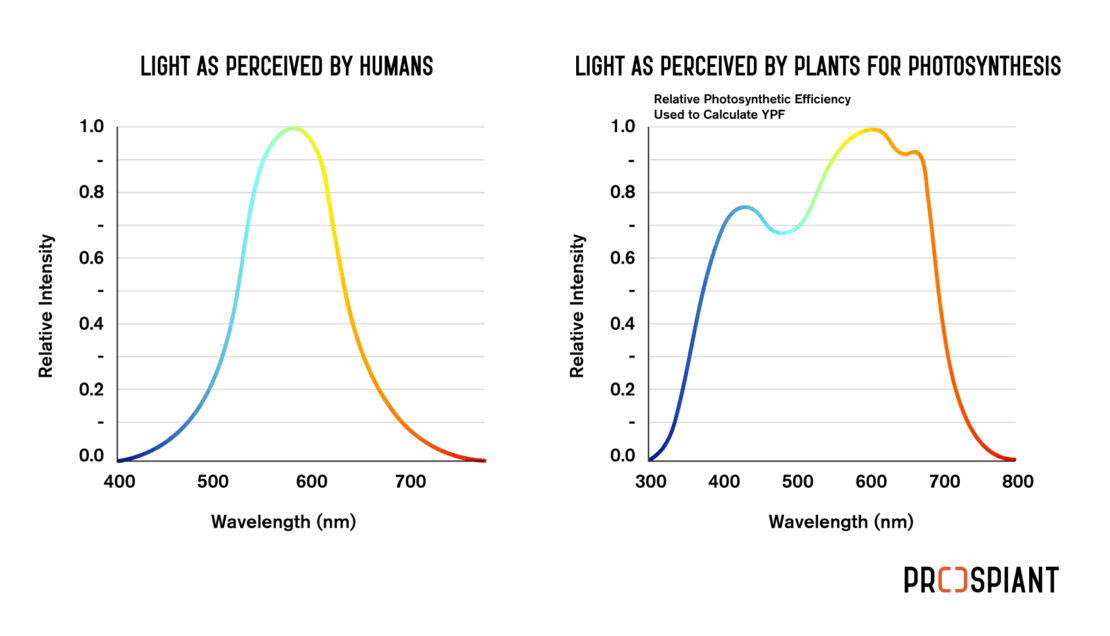

Photosynthetically active radiation (PAR) measures the visible range of the light spectrum plants utilize to perform photosynthesis. As a cannabis grower, you’ll typically only be focusing on the range between 400 to 700 nanometers (nm).

Cannabis plants use different wavelengths of light during each stage of development. In the growing and vegetative stage, cannabis plants utilize blue colored light within the ideal range of 400 – 500 nm. In the flowering stage, they utilize red colored light with spectrum values generally in the 700 nm range.

Pro Tip: When choosing supplementary lighting equipment to optimize your plant growth, ensure you fully understand how much PAR your equipment can produce, how much energy it takes to produce their PAR, and how much PAR is available for these plants before making your purchase.

Photosynthetic Photon Flux Density (PPFD) specifically measures the quantity and intensity of light available to your plants for photosynthesis. It calculates the amount of PAR light photons that reach the plant’s surface per square meter each second in micromoles (μmol/m²/s).

Plants have an optimal light intensity—a point at which photosynthesis is maximized and plant growth is the greatest. However, there is a point where an increase in light intensity and PPFD doesn’t mean increased photosynthesis. This point is called light saturation. When this happens, excess light can generate additional heat that would be detrimental to the growth of the plant.

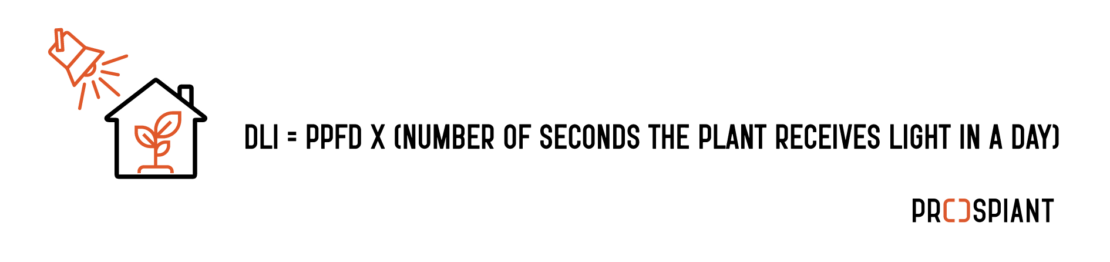

Hence, when purchasing your additional greenhouse lighting equipment, it’s crucial that you consult an experienced vendor to source from responsible manufacturers. With Prospiant, we have a range of customized indoor grow lighting solutions that allow adjustable light intensity and air movement to prevent your crops from overheating. Daily Light Integral (DLI) is the total amount of PAR light intensity your plants receive every day. Cannabis plants in the vegetative stage receive 18 hours of light per day, while those in the flowering stage receive 12 hours of light per day.

For example, if you purchase additional lighting equipment that produces an average PPFD level of 800μmol/m2/s for flowering plants, the DLI will be 51,840,000 μmol/m2 = 51.84 mol/m2.

Understanding how to calculate this metric helps growers determine how much usable light your cannabis crops receive in a day. By understanding how much natural light is being supplied to your plant in your greenhouse, you’ll only need to supply enough supplemental light to bridge the gap between the lowest natural sunlight months and your desired DLI target point. All this comes into play when it comes to choosing greenhouse glazing, roofing, and supplemental lighting options to maximize light transmission and meet your production goals.

Sunlight and the Light Spectrum

To build your greenhouse with the goal of maximizing sunlight transmission, you need to understand how cannabis plants respond to different light variations at each stage of development.

Transmission Through Greenhouse

Plants perceive all seven colors on the light spectrum when the sun shines through your greenhouse. But the two colors that are pivotal to plant growth and yield are blue and red.

When choosing supplemental lighting for your crops, you’ll want to select equipment that allows your crops to hit the blue light peak (430 – 450 nm) and the yellow, orange-to-red peak (640 – 700 nm).

Blue light (430 – 450 nm): Essential for vegetative stage of your cannabis growth cycle. This stage is especially crucial when growers want to eliminate unwanted stretching and stimulate the production of secondary pigments.

Red light (660 – 700 nm): Red light plays an important role in the flowering stage of cannabis plants. At 660 nm wavelength onwards, red light is proven to have a strong photosynthetic reaction on crops.

While exact lighting requirements may vary, research shows that cannabis yields can rise with an increasing PPFD value of up to 1,400 μmol/m2/s.

But several environmental aspects play a role in determining how light intensity affects yields. Increased light intensity is most apparent when the growing environment has higher temperatures and CO2 concentrations.

Pro tip: The same primary or supplemental lighting can’t be used for every stage of growth. Cannabis is a short-day, high DLI crop which means once it starts flowering, long 18-hour photoperiods used in the vegetative growth stage need to be reduced to 12-hour photoperiods. Growers need to account for how this will affect the plant’s DLI requirements. High value crops like cannabis will require around 25-30+ moles of light per day. When supplemental lighting is not utilized to maintain higher DLI’s during the flowering stage, the decrease in photoperiod can greatly restrict your yields and product.

But with customized indoor grow lighting and shading solutions, growers won’t have to worry about early flowering before your maximum crop yield is reached. Growing with Prospiant means you get to leverage decades of cannabis growing expertise to optimize lighting conditions for every stage of your cannabis light cycle.

Now that you know how much sunlight your crops need to grow optimally at each stage of development, it’s time to consider the factors that will optimize light transmission and PAR when constructing your cannabis facility.

Glazings

Your choice of greenhouse glazing could either limit or maximize the sunlight transmission your cannabis crops receive throughout the year. Each glazing material varies in transmittance levels, with various types of coverings that produce a light transmission between the range of 48 – 98%. Your manufacturer should have these light transmission rates readily available.

It’s important to know that the type of glazing also determines the type of light that enters your greenhouse. Growers should also consider the R-value of their chosen glazing type to identify how well the covering insulates against heat loss. High R-values indicate a greater insulating value.

If you’re planning on growing cannabis all year-round, your crops will be exposed to a range of climates that might require you to choose a glazing with higher insulating ability instead of light transmission. In these cases, your experienced vendor will offer supplementary light options to ensure your plants still receive enough light to grow profitably.

Growers typically lean towards polycarbonate, polyethylene, or glass options. But every glazing option has different advantages and setbacks to consider, especially when growing a high DLI crop like cannabis.

Traditional Glass: Traditional glass used to be a common choice among greenhouse growers due to the high light transmittance of about 88 – 92%. The setbacks of choosing glass glazing are high initial costs and maintenance. Glass is also prone to breakage and only produces a moderate R-value of 0.90.

Growers who choose glass glazings are often advised to take additional costs into consideration before making their purchase. But with Prospiant’s latest Venlo greenhouse design, growers benefit from lower square foot costs while retaining the maximum light transmission of the glazing. By using tempered glass, dry roof glazing and reglazing, maintenance costs are effectively minimized.

Anti-Reflective Glass: Anti-reflective (AR) glass is becoming more popular among greenhouse growers as a good choice to maximize daylight transmission and crop yield. After undergoing the AR treatment process, light transmission can increase up to 96%. AR glass is especially beneficial in cannabis cultivation as it enables the transmission of more rays from the light spectrum—allowing your crops to receive more blue and red light.

Polyethylene film: Polyethylene film is one of the most affordable glazing options and is versatile enough to be used for custom greenhouse projects. While this material has a limited average life span of 1-4 years and has a lower R-value as compared to other glazings, newer polyethylene films are being developed with characteristics to enhance energy efficiency and control the condensation inside the greenhouse.

Prospiant has the expertise to help you install the film where you need it—from your roof to the sides and ends of your greenhouse.

Polycarbonate plastic: Polycarbonate glazing has many advantages for commercial year-round greenhouses. It’s lightweight and has a range of different light transmission rates following the number of layers you want to install—from 90% in thinner varieties to under 50% for thicker and tinted varieties. Each layer of polycarbonate glazing can produce an R-value of 1.6. Multi-wall polycarbonate glazing is growing in popularity among growers as it presents higher energy savings than glass.

Whether you’re looking to test out the durability of anti-reflective glass or the diverse versatility of polyethylene and polycarbonate material, our experts at Prospiant can install the covering of your choice easily and expertly. By working together, we can help you select, construct, and maintain the optimal structures and systems to help you maximize light transmission and crop yield.

Change Throughout the Year

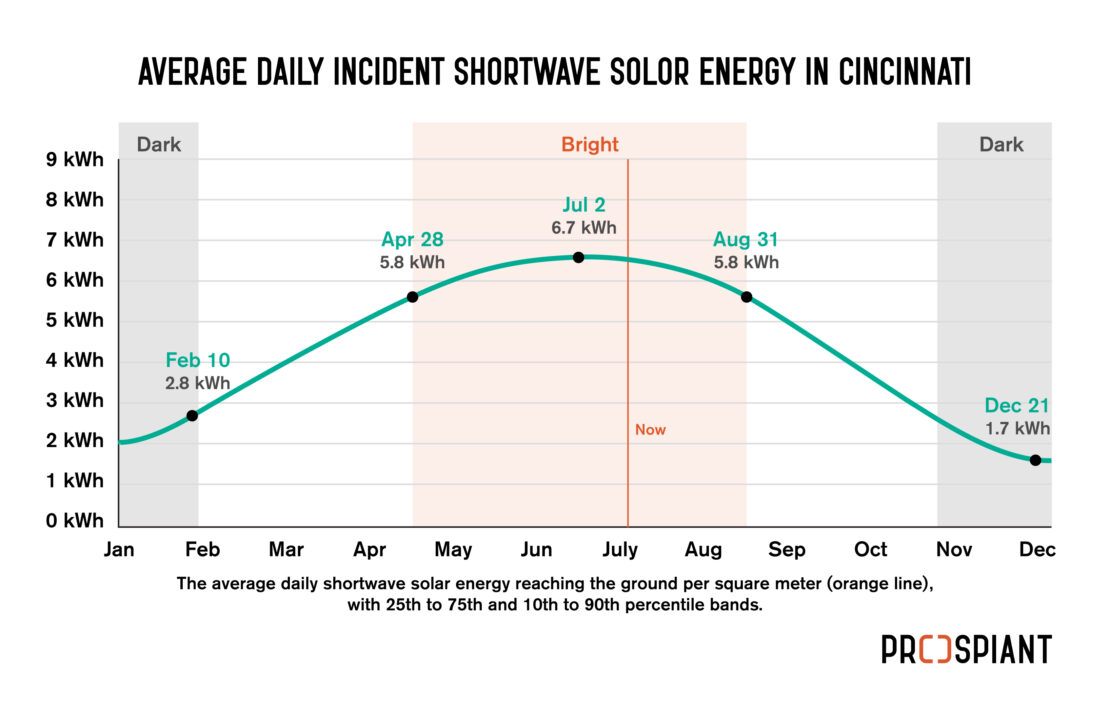

Another crucial factor that helps growers optimize the amount of PAR their crops receive is understanding how sunlight intensity changes throughout the year.

Depending on where you choose to build your cannabis facility, growers should be prepared to face significant seasonal variation over the course of the year. During summer months (April to August), you can expect a high level of PAR with maximized light transmission and an extended photoperiod for your crops.

Whereas during the winter months (November to February), PAR and solar energy will begin to dip. You can expect a shorter photoperiod and less sunlight transmission for your crops. This is where it becomes crucial for growers to install supplemental lighting.

An ideal time for growers to start utilizing supplemental lighting is in the fall, throughout the winter, ending in early spring. As natural light levels decrease throughout the year, supplemental lighting ensures your cannabis crops are still receiving enough light transmission from blue and red light spectrums to hit your yield targets. This strategy allows growers to keep a consistent DLI value and crop quality year-round.

In long winter nights, you can expect to utilize supplemental lighting sources for up to 8 hours a day. Hence, growers should choose cost-efficient lighting equipment that will suit their crop size and production targets to maintain a profitable yield.

While supplemental lighting plays a key role in ensuring your crops receive enough sunlight, growers should also consider greenhouse design and how it corresponds to the sun’s positioning throughout the year to maximize light transmission.

In order to ensure consistent year-round light transmission, growers need to choose a greenhouse design that:

- Minimizes shading from your surrounding environment

- Orients your greenhouse to ensure consistent exposure to the sun

Gutter-connected greenhouses: Growers who choose this specific design should ensure that their cannabis facility is always oriented towards the north or south to minimize shading from trusses.

Free-standing greenhouses: If your free-standing greenhouse has a single bay and is located above the latitude of 40 degrees north, it should be oriented east/west to maximize light transmission from the sides. Alternatively, if your greenhouse is located below the 40 degrees latitude, positioning your facility with a north or south orientation will allow maximum sunlight exposure for year-round growing.

Light Deprivation and Blackout

Every cannabis grower wants to ensure their crops grow as large and healthy as possible in its vegetative stage. But when the crops are ready to flower, growers need to be strategic with how much light their crops receive to ensure maximum consistent yield.

Cannabis is a photosensitive plant. The rule of thumb for cannabis photoperiod is usually set at 18 hours of daylight/6 dark hours during the vegetative stage of growth. At the flowering stage, this changes to 12 hours of daylight/12 dark hours.

Prolonged periods of consistent darkness are taken as a sign for the cannabis plant to start flowering. While this is ideal during the winter when daylight hours are shorter, growers need a sustainable solution that allows them to induce flowering and harvest in long summer days too. That’s where light deprivation technology comes in.

Light deprivation is a strategy used by growers to change the light cycle of flowering plants. With blackout and shaded curtains, growers can selectively block light and deprive their crops of an extended photoperiod. This forces the plant’s instinct to kick in and go into its flowering stage.

When building your cannabis facility, you need to ensure you have the right exterior frame to support a blackout system. Growers must work closely with the contractors during the installation process to ensure their greenhouse trusses are used as starting and stopping points along the ceilings and walls. This allows the trusses to act as a seal when the blackout curtain is pulled against the flat side to stop traces of light from getting into the facility.

Prospiant’s greenhouse design is equipped with a motorized tarp pulley system that rolls a blackout curtain over the top of your greenhouse. Growers also have the option of using gray polyurethane shade curtains for the side walls of the greenhouse to ensure complete light deprivation and an ideal flowering environment.

Pro-tip: Schedule regular maintenance checks with your contractors as these systems may sometimes come out of calibration. Doing daily spot checks on the cables, pulleys, and light sealing edges will help prevent system failure. Responsible growers should also schedule more extensive checks every quarter depending on the climate of your facility location and how often you use your shading system.

But even with a full blackout system in place, a common mistake greenhouse growers make is forgetting the red light illuminated from traditional EXIT signs that are mandated on every door by building regulation codes. The red light perceived by the crops disrupt the plants’ light cycle and could possibly affect crop yield.

To combat this issue, Prospiant covers EXIT signs with a layer of green plastic film to provide plant-safe lighting that doesn’t disrupt your cannabis light cycle during its blackout season. This film is also applied on task-based lighting used by workers who regularly visit your facility.

Effect on Yield

Building a cultivation facility that takes your cannabis lighting requirements into consideration will have a profitable effect on your crop yield. Most of the time, cultivation facilities run on a strict production schedule.

If you’re taking a regular harvest as an example, you’d want your crops to hit vegetative growth for an estimate of four weeks and expect the flowering stage to reach full fruition in eight weeks. Growers who don’t create a controlled lighting environment for their crops to thrive may end up interfering with the plant life cycle—producing lesser, poor-quality yields due to interrupted light cycles during its blackout period.

Growers who plan on building an outdoor cannabis farm should consider how their crops will be severely affected by climate, natural light, external heat, and CO2 levels, as well as interferences from insects and wildlife.

Even with modern agtech developments, outdoor grow farms can produce a maximum of two harvests per year due to environmental restraints. These growers would have to plan and execute the cultivation of their crops around the summer before trimming and extracting during the winter in preparation for the next growing season.

While indoor or hybrid grow facilities like cannabis greenhouses cost a lot more capital, you can reap up to six or seven harvests every year—extending your profit margin by six to eight times as compared to outdoor growing, depending on how well you prepare the necessary lighting conditions for your crops to thrive.

Indoor grow facilities utilize different rooms with specific lighting to foster the development of cannabis plants in their vegetative stage and flowering stage separately. When executed correctly, this could lead to growers producing more yields per square foot as opposed to one bulk harvest.

Having multiple harvests throughout the year also means that you’ll be able to supply the cannabis market with fresh produce all year-round. In the cannabis industry, consumer demand varies from month to month, so having enough produce to sell at every season will help you stay ahead of other cultivators in the competitive market.

HPS vs. LED

When it comes to choosing the right kind of supplemental lighting for your cannabis facility, growers should primarily make their decision based on factors that will help deliver photons to the plant canopy surface. In other words, how efficiently can your equipment transmit light to your crops?

The two main lighting options for growers are high-pressure sodium (HPS) lamps and light-emitting diodes (LEDs). But there are many considerations that growers need to factor in before deciding on the right option for their facilities:

Initial Costs

HPS is the more traditional form of lighting that has been used in growing facilities for decades. It emits a specific type of high-intensity discharge light from the lamps installed in your greenhouse. HPS generates less initial cost as growers can get 1000-watts for just $200 – $300. Annual maintenance costs are also better established for HPS fixtures as compared to LED fixtures.

LEDs on the other hand are more energy efficient but cost around $800 to $1,000 for initial start-up per light fixture. Some LED fixtures even exceed the efficiency of HPS fixtures by 23%. They produce more light levels than HPS fixtures kilowatt-for-kilowatt and are superior at converting electricity to light. This means that it would take less LEDs than HPS lamps with similar wattages to produce the same amount of light—effectively reducing your electricity costs.

Longevity

Even though LEDs cost three to five times more than HPS fixtures, LEDs are often promoted as the more durable option as they have a significantly lower operating cost due to their longevity and ability to generate 50,000 – 100,000 hours of light in their lifetime. If you’re planning on using supplemental lighting for an average of 16 hours a day, this means your LEDs have a lifespan of about 10 – 20 years.

On the other hand, HPS fixtures become dimmer they longer the run—they instantly begin to diminish in light output the second they are turned on. Double-ended HPS lamps (1000-W) have a life expectancy of 10,000 to 17,000 hours and 90% survival of up to one and a half years on an average usage of 16 hours a day.

Light quality

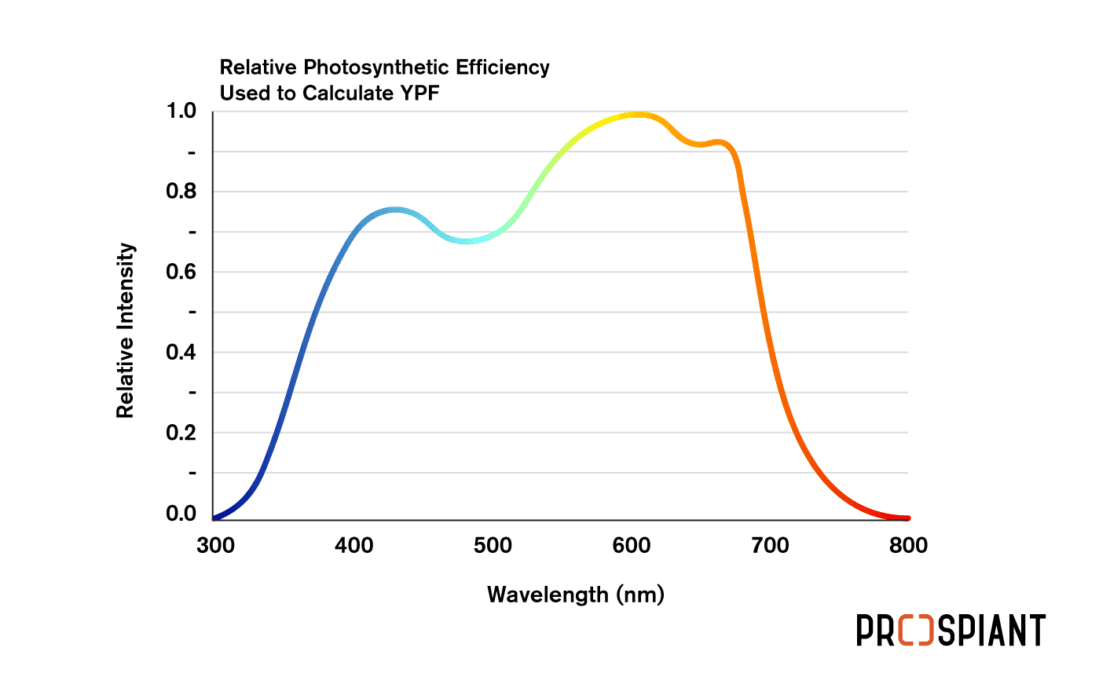

Many growers believe the misconception that light quality is the main factor that increases plant growth. But a more accurate way of estimating the effect of light on photosynthesis is through the Yield Photon Flux (YPF) curve. This curve indicates that orange and red photons between 600 nm and 630 nm can result in 20 – 30% more photosynthesis than blue and cyan photons between 400nm and 500nm.

From this curve, HPS lamps can be said to have equal or even better effects than LED fixtures due to the high photon output they produce in the red light spectrum and the lower photon output they produce in the blue, cyan, and green light spectrums. LEDs generate blue, red, and cool white lights from the light spectrum but lack far-red radiation which helps crops grow better in their flowering stage. Growers should take note that LEDs can provide light on different spectrums but HPS fixtures don’t have this ability.

Heat and HVAC usage

HPS fixtures produce infrared lights which generates thermal radiation from the front of other lamps. While this is useful in warming the plant canopy, it can be detrimental to plant health during the long summer days. Growers who install HPS fixtures will need to factor in increased air-conditioning utilization to maintain optimal temperature for plant growth which could add up to higher electricity costs.

In comparison, LEDs create much less heat as compared to HPS fixtures. Some LED growers save as much as 30-40% on air-conditioning costs when switching from HPS. If you’re designing your indoor facility from ground up, you can request for your vendor to customize a smaller HVAC system to lower your capital expenditure.