Building a commercial greenhouse can be a rewarding project for professional growers. A fully functional controlled environment agriculture (CEA) facility offers an unparalleled command of growing conditions to promote better quality crops and higher yields. A commercial greenhouse can drive efficiency and even reduce operating costs over time.

However, a commercial greenhouse is a serious investment and there are considerable costs involved with construction, installation, and other building requirements. Many of these costs could be expected with any commercial construction project. But since commercial greenhouses provide a fully controlled growing environment, there are unique expenses associated with commercial greenhouse construction costs.

Commercial greenhouse costs can vary greatly. Knowing what goes into building a CEA growing facility and the related average costs can be instrumental in understanding what contributes to the overall price of building a commercial greenhouse.

Get started on your commercial greenhouse project with Prospiant

When Is the Right Time to Build A Commercial Greenhouse

Commercial greenhouses are meant for large-scale growing operations. There are plenty of great greenhouse construction options available for hobbyist growers but the high-tech equipment, size of facilities, and even quality of materials are specific to commercial greenhouses.

For those just starting out in agribusiness, a fully outfitted commercial greenhouse is probably not the right choice. But established farmers looking to diversify their operations are perfect candidates for commercial-scale indoor growing.

There’s never been a better time to build a commercial greenhouse. CEA-driven growing operations are becoming more popular than ever, with an 115% increase in greenhouse vegetable farms in the US since 20101.

As global warming and extreme weather events continue to disrupt growing around the world, the food security of millions may depend on stable indoor growing. There’s a real need for an alternative to conventional farming, and commercial greenhouses provide a peerless solution.

For commercial growers frustrated with the limits of traditional outdoor farming, CEA facilities provide greater control to cultivate greater crops. Plants can be grown far beyond their regular growing season, which allows farmers to meet the increasing demands of consumers who want fresh local produce all year round.

But before starting a commercial greenhouse project, there are some construction factors that should be evaluated to better understand commercial greenhouse cost.

Planning is crucial when it comes to managing commercial greenhouse construction costs. Expenses can accumulate quickly, so it’s important to consider every square foot of the facility before committing to building.

Commercial greenhouse construction depends on the availability of commercial real estate with sufficient space to build, enough sunlight and water to satisfy indoor growing needs, and room to expand operations in the future.

The right location is highly important, and zoning regulations and local construction laws should be considered for the best building outcomes. Also, choosing the type of greenhouse structure and the type of crops beforehand will help to streamline construction operations.

And of course, having strong funding to cover commercial greenhouse construction costs is essential. Whether it’s a construction loan, capital from investors, or any other type of financial backing, commercial greenhouses cost per square foot can be substantial and finances need to be in order before beginning the project.

Budgeting Your Commercial Greenhouse

The construction of a commercial greenhouse depends on factors like cost of labor, materials, and various construction fees. Installation, operation, and maintenance of an indoor farming facility come at a higher cost than conventional open field farming, and budgeting ahead of time can spare growers headaches later. The structural frame and covering material will be significant expenses but there are other commercial greenhouse construction costs that should also be factored into the budget of the project.

Important things to budget for include:

- Irrigation system

- Heating system

- Lighting system

- Material costs

- HVAC and filtration system

- Carbon dioxide fertilization system

- Staffing and labor

- Energy costs

What is the Construction Cost per Square Foot for a Commercial Greenhouse?

Average commercial greenhouse cost is usually about $25 per square foot.2 So, a standard 1,000 square foot greenhouse would probably cost about $25,000 to build.3 This price is influenced by market conditions around the price of steel and framing materials, supply chain efficiency, and even consumer demand for building materials. And the more sophisticated the technology incorporated into a commercial greenhouse is, the higher the price per square foot.

Commercial greenhouse construction costs can vary wildly depending on the growing needs of the operation. And while $25 per square foot is an average price, that cost per square foot can be influenced by a wide variety of factors.

Factors Influencing The Overall Cost Of Your Commercial Greenhouse

Commercial greenhouses are highly customizable. It’s unlikely to find two commercial

growing operations with matching structure, layout, and equipment. Different crops have different growing requirements which dictate the overall commercial greenhouse costs. But while there are many factors affecting the overall cost of your commercial greenhouse, most can be adjusted to fit your budget.

Covering Material

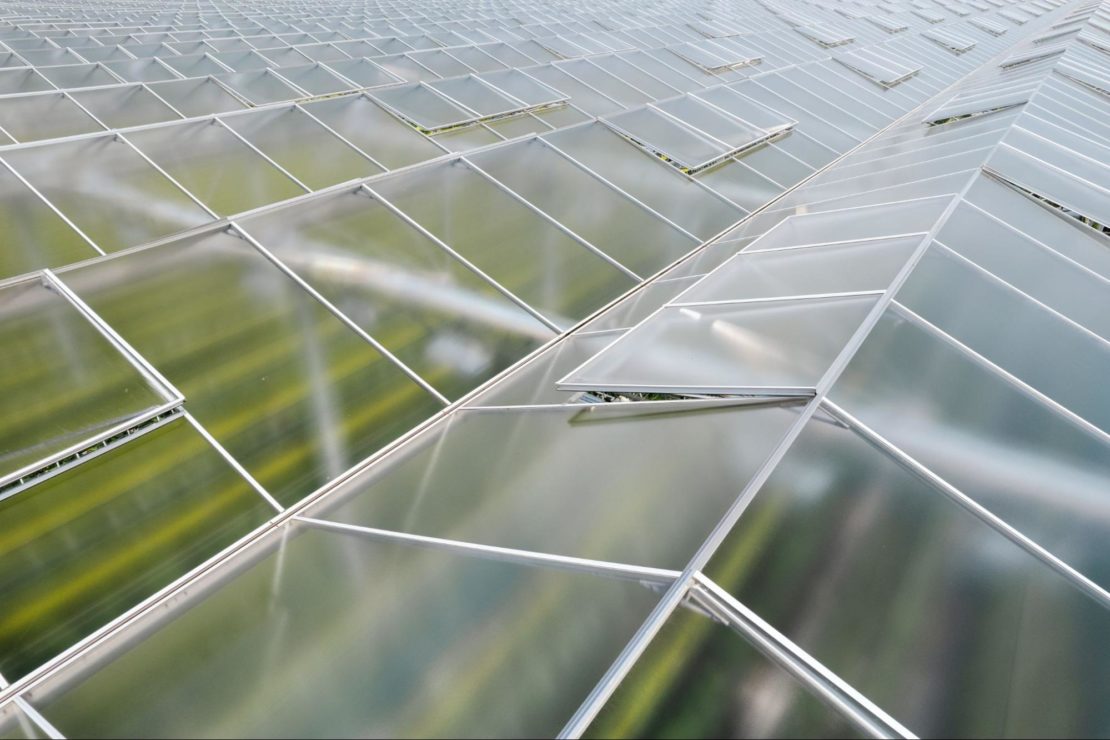

The covering material of a greenhouse is essential in controlling the amount of light and heat that a greenhouse receives, as well as regulating energy costs. There are several types of covering material for commercial greenhouses, each with their own unique benefits.

Glass

If properly cared for, glass material can provide superior light transmission and light clarity than polycarbonate. It’s generally more aesthetically pleasing than polycarbonate and is usually available in a variety of layering options to promote ventilation and insulation. Glass greenhouses are also highly resilient to fire, rain, and snow and can resist UV damage. On average, glass siding can cost about $2.50 per square foot.4

Polycarbonate

Polycarbonate is more durable and cost-effective than glass. It can also retain heat more efficiently and provide protection from harmful UV rays. Polycarbonate is flexible and can be more easily shaped to the specific structural requirements of a Greenhouse. Depending on the grade, polycarbonate costs between $0.90 and $2.20 per square foot.5

Polyethylene Film

Like polycarbonate, polyethylene film is a flexible covering material available in various thicknesses. Often used to cover a hoop greenhouse, this is perhaps the easiest covering material to install at the most cost effective price. Poly film products with UV additives are highly efficient at transmitting light and promoting air circulation. However, polyethylene is prone to damage and is the least durable of any covering material for greenhouses. This material is relatively inexpensive and can cost as little as $0.12 per square foot.6

Acrylic

Rigid acrylic panels are a highly durable covering material that can last for decades with proper care. Acrylic covering materials are sold in multiple layers to provide optimum insulation. This material is lightweight and flexible and can be cut and bent to custom sizes. It’s weather resistant and offers high light transmission. While not quite as fragile as glass, acrylic panels do need to be treated with more care than polycarbonate or polyethylene products. Depending on thickness, acrylic converting can cost between $1.95 to $3.00 per square foot.7

Frame Material

Frame material is crucial for ensuring the structural integrity of commercial greenhouses. While PVC frames are perfectly appropriate for home growing projects, commercial operations need more durable options.

The two primary frame materials used in commercial operations are metal and wood, which each have their own respective subcategories. Wood materials can cost as low as $1.00 per linear foot while steel frames are usually priced at about $2.50 per square foot.8

Metal frame material has a greater initial cost but is far less susceptible to damage and will generally last longer than wooden materials.

Temperature Controls

Properly regulated temperatures give greenhouse farmers the ability to grow quality crops in virtually any climate. Thermostats and heat sensors are essential for maintaining optimal growing conditions and preventing plant stress. Heaters powered by natural gas or propane can be easily regulated with proper controls.

Electronic thermostats have been widely adopted for use in commercial greenhouses. They can be integrated with heating and cooling systems and even automated to provide immediate adjustments to the indoor climate. An electronic thermostat for commercial use can cost between $600 to $1500 to install.9

Irrigation

Most commercial greenhouses use overhead sprinklers or drip irrigation systems to provide water to their plants. These irrigation methods can be automated for consistent, regular watering or even managed by an artificial intelligence (AI) software to provide precise amounts of water exactly when plants need it.

The largest and most complex sprinkler systems can cost up to $12 per square foot.10 A commercial grade drip irrigation system can cost between $450 to $624 to install.11

Lighting

Lighting considerations are important for commercial greenhouse growers. Many commercial greenhouses are now relying on LED grow lights to provide extra illumination. LED grow lights are energy efficient, long-lasting, and have a flexible light spectrum that can be adjusted to the tastes of particular greenhouse crops. On average, LED lights cost $0.13 cents to run per kilowatt-hour per light or about $47 per month.12

HVAC Systems

A quality HVAC system helps to regulate temperature and airflow in a greenhouse building. These systems can be installed as a unit or separated into individual components of heating, ventilation, and air conditioning. A typical HVAC system for a commercial greenhouse can cost $5,000 or more to install. Ventilation fans usually cost $125 on average.13

Flooring

Flooring isn’t necessarily vital for greenhouses but it can make a noticeable difference in pest control, weed growth, and insulation. The right flooring can also provide extra support to employees working on their feet. Concrete flooring can cost between $2.00 and $6.00 per square foot while rolled rubber flooring is usually available for around $2.00 per square foot.14

What Size Should Your Commercial Greenhouse Be?

The size of your commercial greenhouse should depend on the size of your operations.

Generally, the larger the size of a greenhouse, the more it will cost to build. But that’s not necessarily bad news. A large-scale commercial greenhouse will be able to accommodate more plants and produce higher yields, translating to bigger profits.

Most commercial greenhouses are at least 20 feet wide by 300 feet long for a total of 6,000 square feet.15 Really, there’s no industry specified standard size for greenhouses, and the exact dimensions of the facility are up to the grower and their desired amount of growing space.

But bigger is usually better when it comes to commercial plant growth and cultivation. Larger size allows for optimized placement of crops, aisles, benches, and other greenhouse building standards.

Larger greenhouses are generally better suited for high quality equipment and technology. It wouldn’t make much financial sense to install an automated irrigation system in a mid-scale rooftop greenhouse, hydroponic greenhouse, or pit greenhouse, but cutting-edge agriculture technology is perfectly suited for commercial growing.

The Prospiant Solution

If you need a technology-backed commercial greenhouse solution that works with your budget, trust Prospiant. We strive to provide our partners with all the support they need to accelerate their controlled environment agriculture efforts.

At Prospiant, we help you create a complete produce ecosystem. From architectural design to general contracting and HVAC, your partners at Prospiant will support you through every square foot of the commercial greenhouse construction process. We know the right type of structure, construction materials, and equipment for you to achieve sustained growing and cultivation success.

Prospiant is your source for cost-effective commercial greenhouse cultivation facilities — all backed by decades of in-house expertise. We’ll guide you through every square foot of your project, ensuring that your greenhouse aligns with your operational goals.

We specialize in designing and building controlled environment agriculture solutions for businesses of all sizes. You’ll get a complete produce ecosystem tailored to your unique needs with all the support you need for greenhouse farming success. Whether you specialize in one crop or want to grow a variety of fruits and vegetables, we have the solution for you.

When you need to set up, get growing, prove profitability, and scale fast, choose Prospiant.

FAQs

How much does it cost to build a 1-acre greenhouse?

A one-acre greenhouse would be a massive growing facility reserved for only the most competitive commercial farming operations. The cost of building such a large facility can vary based on several factors, including the specific crops grown, geographic location, terrain, greenhouse type, and more.

Fluctuations in material costs due to supply chain issues and demand can also impact overall expenses. Installation costs are subject to variations based on individual preferences. Conducting thorough research, consulting with a knowledgeable supplier, obtaining accurate quotes, and more are essential to determining an accurate price. Doing your due diligence in these areas will ensure that the greenhouse you select meets your growing needs and fits your budget.

What is a good size for a commercial greenhouse?

While there’s no specific standard size for a commercial greenhouse, most are at least 20 feet wide. This width can accommodate more plant growth space, aisles, and benches for optimal productivity.

Citations

1https://www.hortidaily.com/article/37151/New-North-American-greenhouse-statistics-available/

2https://www.homeadvisor.com/cost/outdoor-living/build-a-greenhouse/

3https://www.forbes.com/advisor/home-improvement/greenhouse-cost/

4https://www.forbes.com/advisor/home-improvement/greenhouse-cost/

5https://www.usgr.com/greenhouse-coverings/greenhouse-coverings/#:~:text=Polycarbonate%20costs%20from%20%240.90%20to,depending%20on%20grade%20and%20quantity.

6https://www.forbes.com/advisor/home-improvement/greenhouse-cost/

7https://www.usgr.com/greenhouse-coverings/greenhouse-coverings/#:~:text=Polycarbonate%20costs%20from%20%240.90%20to,depending%20on%20grade%20and%20quantity

8https://www.forbes.com/advisor/home-improvement/greenhouse-cost/

9https://www.alliedbuildings.com/commercial-greenhouse/

10https://www.made-in-china.com/products-search/hot-china-products/Greenhouse_Irrigation_System_Price.html

11https://www.angi.com/articles/drip-irrigation-cuts-down-yard-work-water-usage.htm

12https://www.dormgrow.com/blog/how-much-will-it-cost-to-run-led-grow-lights/

13https://www.alliedbuildings.com/commercial-greenhouse/

14https://www.forbes.com/advisor/home-improvement/greenhouse-cost/

15https://www.ourendangeredworld.com/eco/commercial-greenhouse-construction-costs-per-square-foot/