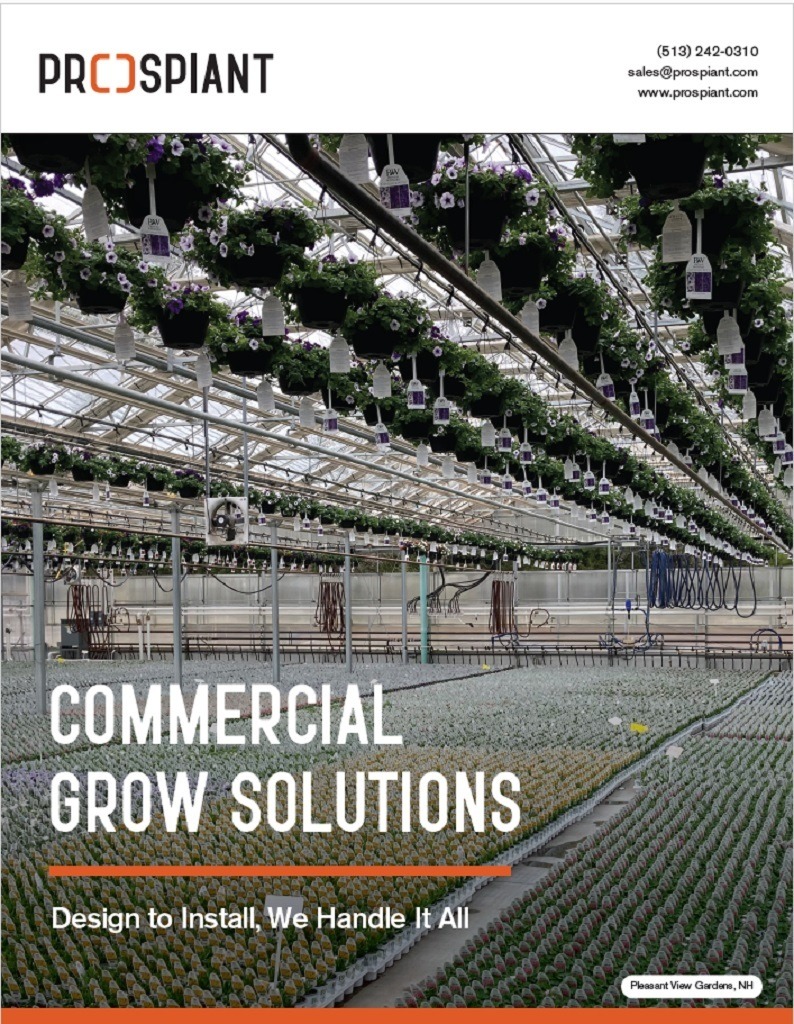

When valuable time spent hand watering hanging baskets becomes unsustainable or simply mind-numbingly tedious, hanging basket commercial greenhouse watering systems offer an excellent solution to your problems, particularly when you have a lot of square footage under production.

While hanging up baskets over ground-floor production maximizes space and profits, routine tasks such as watering and scouting take on a new level of difficulty.

Hanging basket commercial greenhouse watering systems make these tasks easier and more efficient while requiring less manual labor.

Watering transitions to a targeted approach that uses less water when growers use an automatic watering system for their hanging baskets. Plant quality improves.

Hanging basket watering systems range from stationary systems to those that utilize pulleys to fully automated cable or chain systems. Your production square footage, labor requirements, style of greenhouse, and crop needs help determine which system will work best for you.

Types of Hanging Basket Watering Systems

Stationary Systems

A typical stationary hanging basket irrigation system uses a rail pipe to suspend baskets from the trusses. Employees walk to and from the hangers to load and unload the baskets.

Spaghetti tubes with emitters on their ends extend from an overhead water line to drip irrigate each basket. The emitters control the flow and volume of the water.

Cable/Chain Systems

More advanced cable-drive basket systems control everything from a central location. The hanging baskets come to the worker instead of the worker going to the baskets.

Cable-drive systems attach to the bottom truss chords. They have two drums —a driving drum and an idle drum— located on opposite sides of the greenhouse bay. Hanging baskets suspend from hooks attached to a cable loop that stretches between the two drums. A variable-speed gear motor runs the drive drum to control the speed of the cable for watering and loading/unloading.

Automated basket systems help maintain crop uniformity by minimizing the impacts of varying light levels throughout the greenhouse.

As each basket traverses the entire path of the cable or chain circuit each day (or multiple times a day), the variability of light (caused by shadowing, sun angle, etc.) is spread more equally across the crop.

Irrigation occurs in one area with these systems as the moving baskets pass underneath a water nozzle. Most systems can accommodate various pot sizes and allow for adjustments to hook spacing. Some growers even use two different hook lengths on their automated basket systems to double-stack baskets for higher density production.

Other hanging basket systems use a heavy-duty chain instead of a cable for smoother movement through the greenhouse with less vibration. Baskets hang from hooks attached to the chain.

Growers can lower the chain track to access the baskets for routine plant care, and the track can continue to run while this occurs. Some chain-driven systems also pitch downward to make loading and unloading easier.

Another improvement to hanging basket systems includes ones that water entirely by weight using scales and sensors. This veers from the traditional water-by-time standard to an approach where the grower programs in an ideal weight for the crop, which then receives only the water it needs to minimize waste.

Highlights

- Simplified installation and user-friendly operation

- Allow for the convenience of automated self-watering

- Efficiently reduce water consumption

- Enhance labor productivity with boosted efficiency

- Optimize vertical greenhouse space

- Facilitate transportation to a central area, if required

- Supply consistent water volumes for uniform crop growth

- Reduce susceptibility to human error, preventing over- or under-watering issues

- Minimize impacts of varying light levels throughout the greenhouse

- Maintain crop uniformity

Prospiant offers several options for greenhouse structures that support hanging basket systems and multi-tier production. Check out our Windjammer, Grand Teton, Vail and Dual Atrium greenhouses.

Stop hand watering those hard-to-reach baskets.

Let Prospiant help you choose the right hanging basket commercial greenhouse watering system for your growing needs.

Commercial Brochure

Overview of our offerings for commercial growing – floriculture, ornamentals, etc.

Case Study: Greenhouse Research Facility – The University of Nevada

Read about our new University of Nevada, Reno, Greenhouse Research Facility.

Case Study: White Oak Garden Center

Read our case study on the White Oak Garden Center in Cincinnati, OH