Commercial Greenhouse Farming is the Future of Food

The future of farming starts with commercial greenhouses. Traditional outdoor farming can be unreliable. Threats of pests, disease, extreme weather, and lack of natural resources make it difficult for fruit and vegetable farms to consistently grow quality crops at high yields. After all, even the best farmers can’t control every growing condition in their fields, orchards, or vineyards.

That’s why it’s never been so important to invest in controlled environment agriculture (CEA). Commercial greenhouses backed by CEA technology provide a sustainable solution to addressing the food security needs of the coming decades.

Growing conditions can be accurately monitored and adjusted in real-time, giving plants the exact care they need to thrive. Temperature, humidity, light, irrigation and more are all able to be controlled in a stable indoor environment without interruptions from the outside world.

Growing in a fully controlled indoor environment gives commercial farmers the ability to produce crops year-round. From fruits and vegetables to herbs and flowers, commercial greenhouses promote higher yields, lower production and maintenance costs, and year-round growing.

With vertical farming and indoor growing becoming more popular, the commercial greenhouse market is prospering and is only predicted to grow in the future. As traditional farming techniques become less viable and more consumers demand fresh local produce, commercial greenhouse farming is the solution.

Get started with your Commercial Greenhouse project

What Does Greenhouse Farming Involve?

Greenhouse farming can vary depending on the particular crops and the size of the growing operation. Different greenhouse structures, equipment, and technology all play a role in commercial greenhouse farming. Every crop needs a different approach to care and management.

Flexibility and customization are essential in ensuring each crop can grow to its fullest in a cost-effective way. While some commercial growers may specialize in only one type of crop, others need to grow a variety of crops to satisfy their bottom line. Greenhouse farming gives growers the ability to set up different buildings for different crops. One greenhouse can grow tropical plants while another can grow more temperate fruits and vegetables.

Greenhouse farming involves a harmony of different systems to grow the best quality crops. The design and construction of the building are crucial to overall growing success, but other factors in the controlled growing environment are equally important.

Temperature and Humidity

For growers in cooler climates, temperature is the biggest advantage of greenhouse farming. That’s not to say that properly regulating greenhouse temperatures isn’t important for all commercial farmers, but the ability to grow quality crops in virtually any climate is certainly appealing to fruit and vegetable farms in regions with traditionally short growing seasons.

It’s important for plants to grow in the most suitable environment, and the wrong temperature and humidity can have a big impact on plant stress. When plants are stressed, they not only grow less but also become more susceptible to disease and mold.

Greenhouses depend on heating and cooling systems to grow the best crops. And while providing enough heat is key to successful growing in colder climates, it’s equally important to cool the air.

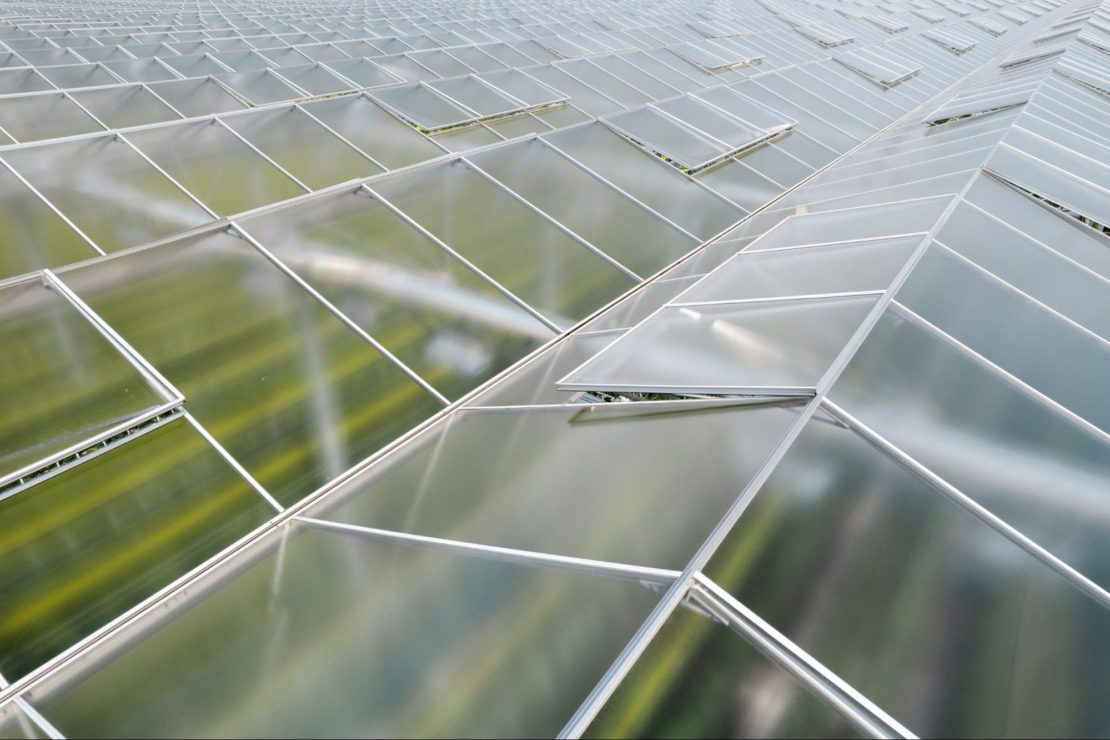

Commonly used equipment for cooling includes fans, vents, shade curtains, and fogging systems. For heating concerns, many greenhouses can depend on natural sunlight to warm the building. Greenhouse structures are designed with transparent or semi-transparent glass, fiberglass, or polyethylene walls to allow solar rays to provide light and warmth.

However, sunlight alone might not be enough to meet the temperature needs of certain plants. Many greenhouses rely on heating systems to warm their facilities. Heating equipment may be powered by propane or natural gas or may be strictly electric.

Irrigation

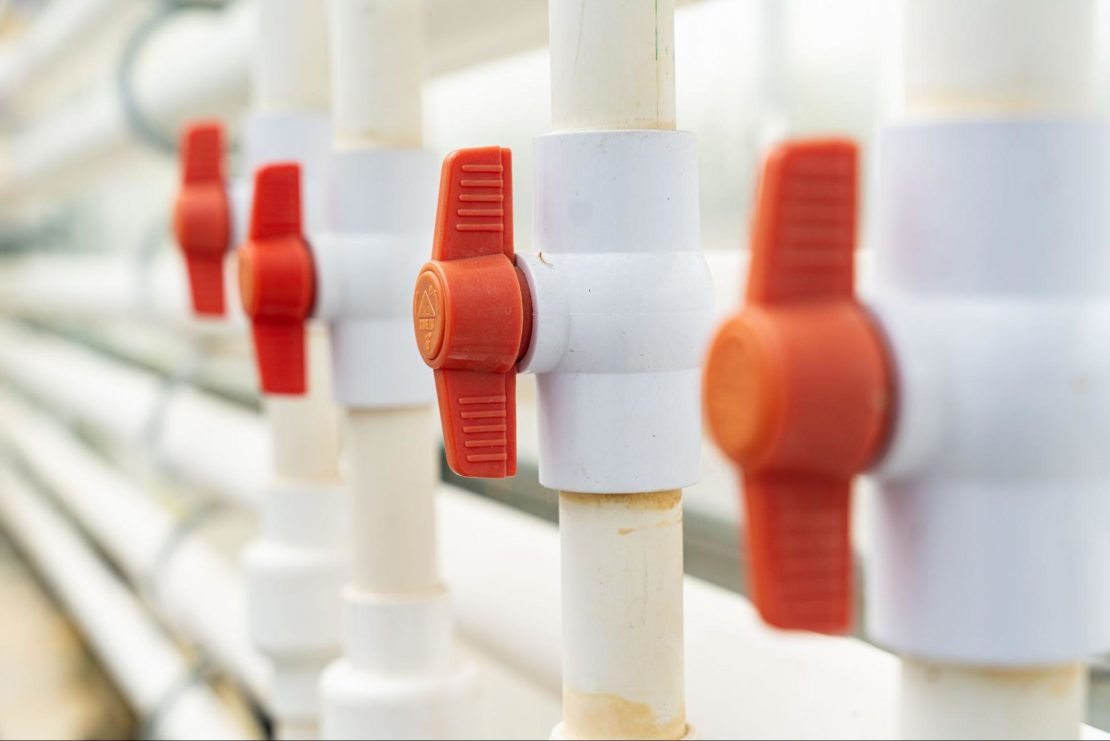

Just like different plants have different temperature and humidity needs, they also have different requirements for water. There are a variety of irrigation systems available for commercial greenhouses. Considerations like greenhouse size, plant types, and even time all factor into the use of irrigation systems.

Hobbyists and smaller fruit and vegetable farms may use self-watering trays and capillary mats to meet their irrigation needs. This method is fairly straightforward and affordable but requires manual labor and isn’t easily automated for larger growing operations.

Most commercial greenhouses use overhead sprinklers, misting systems, drip irrigation systems, or soaker hoses to provide water to their plants. These irrigation methods can be automated for consistent, regular watering or even managed by an artificial intelligence (AI) software to provide precise amounts of water exactly when plants need it.

Commercial growing operations rely on automated technologies to manage greenhouse crops in place of manual labor. Watering every individual plant by hand would be incredibly inefficient. Automated irrigation systems save time, drive efficiency, reduce costs, and give commercial greenhouse growers more time to focus on other business needs.

Lighting

Greenhouses are built to receive maximum amounts of sunlight for growing plants. But in regions that have limited daylight hours, the sun alone isn’t enough to supply plants with the light they need to grow.

Lighting considerations are fundamentally important for commercial greenhouse users. Many commercial greenhouses are now relying on LED lights to provide extra illumination. LED lights are energy efficient and long-lasting and have a flexible light spectrum that can be adjusted to the tastes of particular greenhouse crops.

Like irrigation and temperature control systems, greenhouse lighting can be automated to minimize human inputs and save labor. High pressure sodium (HPS) and metal halide (MH) lamps are still widely used in many growing operations, but the flexibility of LEDs is making them an increasingly popular choice

Growing Media

Many greenhouses use a hydroponic system to grow their crops, which means plants are grown without the use of soil. However, some kind of substrate or growing media is usually required for most plants to root themselves and grow. As with nearly every aspect of greenhouse production, the right type of growing media depends on considerations like crop type and production system.

Growing media can be natural or made of artificial or inorganic substances. Common substrates include Rockwool, coconut fiber, or peat. Substrates need to drain well enough to avoid growth of mildew, mold, and microorganisms but also retain enough moisture to satisfy the growing needs of plants.

Fertilization

Artificially increasing carbon dioxide levels can have dramatic effects on crop yield. Many commercial greenhouses use a CO2 fertilization system to boost plant growth. This is typically done with the use of a CO2 generator or with a carbon dioxide system integrated into the facility using pipes.

Taken together, these systems form the basis of greenhouse operations. There are also considerations of labor and staffing, shipping and receiving, and other common business concerns.

Advantages of Running a Greenhouse Farming Business

Compared to conventional farming, there are many advantages to running a business in the greenhouse industry. CEA greenhouses help growers to regulate growing conditions, and this environmental control has substantial benefits.

Increased Yield

Crops grown in greenhouses supported by CEA technology are far more likely to grow faster and fuller than those grown outdoors. Plants can grow in a protected growing environment suited to their exact needs, allowing for optimum greenhouse production.

Extended Growing Season

Greenhouse crops aren’t dependent on the cycle of seasons to grow. Environmental controls can effectively simulate the exact climate conditions that specific crops need.

Smaller Carbon Footprint

Through utilization of alternative energy resources and eliminating waste production, greenhouses can modify their operations to emit less CO2.

Maximized Profits

Higher crop yields can boost revenue, especially when crops can be grown year-round. Along with cost-saving electric and irrigation systems, greenhouse farmers can enjoy steady return on investment for their growing efforts. Read more about a commercial greenhouse cost.

Improved Efficiency

Having complete control over the growing environment promotes greater overall efficiency in greenhouse operations. Production can continue year round and thanks to technological innovations, resources can be managed more easily.

Weather Protection

As catastrophic weather events increase around the world, a quality greenhouse can protect crops from damage. Heavy rain, snow, wind, drought, and other weather conditions won’t affect plants when they’re housed in a controlled growing environment.

Pest Control

Tightly controlled growing environments prevent foreign objects and unwanted pests from penetrating the greenhouse. In the wild, pests can infest crops without warning. But in a CEA-driven greenhouse, pest problems are minimized and can be more easily contained in the event of an infestation.

While greenhouse farming also comes with upfront costs and ongoing operating expenses, the advantages far outweigh the disadvantages. Growers looking to cultivate sensitive crops or crops that are typically not seasonally available have a unique opportunity to succeed with commercial greenhouses.

How to Choose the Right Commercial Greenhouse

Commercial greenhouses come in an impressive range of shapes and styles. Greenhouse structures are designed to promote the best possible growing conditions but can also be aesthetically pleasing.

There are many different types of greenhouse structures, materials, and equipment to consider when choosing the right commercial greenhouse for your operations. Every greenhouse design has its own strengths. Some may be better suited for growing fruits and vegetables while others may be better for flowers and botanicals.

Considerations like ventilation, insulation, UV protection, durability, and customization are all important to account for when choosing a commercial greenhouse.

Structure

The greenhouse structure will dictate all other aspects of growing operations. The available interior space must account for the number of plants, space for workers, as well as relevant growing systems like irrigation, heating, and lighting. Broadly, there are two main types of greenhouse structures for commercial use.

Freestanding Greenhouses

Freestanding greenhouses, sometimes also called detached greenhouses, stand independently from one another. They can come in a variety of shapes including Quonset, Gothic arch, gable shaped, and A-frame roof. A freestanding greenhouse is designed to disperse maximum amounts of sunlight over the entire growing area and is typically suitable for most crops.

Ridge and Furrow

Ridge and furrow greenhouses are connected by a common gutter system. Several ridge and furrow buildings can be joined to create a range of greenhouses without interior walls separating them. This type of greenhouse is usually gabled or curved and is often considered the most economical.

Covering Material

Greenhouse covering material can make a dramatic difference not just in the amount of light and heat that a greenhouse receives, but also in energy costs. The two most popular types of greenhouse covering materials are glass and polycarbonate.

Polycarbonate

Polycarbonate is a popular choice for commercial greenhouses because it’s more durable and cost-effective than glass. Thick polycarbonate material can also retain heat more efficiently and provide protection from harmful UV rays. Polycarbonate is also flexible and can be more easily shaped to the specific structural requirements of a greenhouse.

Glass

If properly cared for, glass material can provide superior light transmission and light clarity than polycarbonate. It’s generally more aesthetically pleasing than polycarbonate and is usually available in a variety of layering options to promote ventilation and insulation. Glass greenhouses are also highly resilient to fire, rain, and snow and can resist UV damage.

No matter what type of greenhouse you’re looking for, the experts at Prospiant will work with you to find the best greenhouse structures for your growing and cultivation efforts. We have a wide variety of quality customizable commercial greenhouses for growers to choose from, including:

The Vail Atrium

A versatile greenhouse for crops at all stages with easy to operate roof vertical roof vents

The Venlo

A cost-effective glass greenhouse with maximum light transmission

The Dual Atrium

A commercial greenhouse with vertical roof venting for reduced need of cooling systems

The Grand Teton

A Gothic arch design greenhouse with exceptional condensate control at a competitive price

What Type of Commercial Greenhouse Layout Do I Need?

Layout is sometimes overlooked when weighing commercial greenhouse options. In order for CEA facilities to function properly, greenhouses need to be designed with factors like headhouse location, interior space utilization, parking, storage, and outdoor production in mind.

Greenhouse operations involve more than just growing and cultivation. Workflow and logical placement of related buildings must be thoroughly considered to optimize productivity.

A good layout for a commercial greenhouse operation usually centers around the greenhouses themselves, which should be located in an area with good light and proximity to water.

Commercial greenhouse layouts typically include a headhouse, which functions as an administrative workspace. Production and storage rooms should be located close to shipping and receiving areas for maximum efficiency. It’s also generally recommended to leave extra acreage available for future expansion.

Prospiant: Your Trusted Commercial Greenhouse Farming Solution

If you need a technology-backed commercial greenhouse solution, trust Prospiant. We strive to provide our partners with all the support they need to accelerate their controlled environment agriculture efforts.

Prospiant is your source for commercial greenhouse cultivation facilities — all backed by decades of in-house expertise. We’ll guide you through every stage of your project, ensuring that your greenhouse aligns with your operational goals.

We specialize in designing and building controlled environment agriculture solutions for businesses of all sizes. You’ll get a complete produce ecosystem tailored to your unique needs with all the support you need for greenhouse farming success. Whether you specialize in one crop or want to grow a variety of fruits and vegetables, we have the solution for you.

When you need to set up, get growing, prove profitability, and scale fast, choose Prospiant.

FAQs

What material is needed for a commercial greenhouse?

Galvanized steel and aluminum are some of the most common structural materials used for commercial greenhouses. Flooring is usually concrete. Covering materials are typically made of glass, acrylic, polyethylene film, or polycarbonate.

How big is a commercial greenhouse?

Most commercial greenhouses have a width of at least 20 feet or more. At this size, a large-scale commercial greenhouse can accommodate multiple aisles and growing benches for maximum growing efficiency.