If energy-efficient practices don’t rank high on your list of priorities for greenhouse environmental management, you are doing your greenhouse operation a disservice. Energy consumption impacts your bottom line, not to mention the preservation of natural resources. These things may not worry you now, but that could change quickly in the future. Incorporating energy-efficient practices into your growing operation might be the best thing you ever do for the long-term health of your business.

In more ways than one, becoming an energy-efficient organization has benefits beyond cost-savings. Given that energy code changes are already occurring in some areas, it’s essential to be proactive in preparing for the impact of future energy regulations, regardless of what crop(s) you grow. Brand reputations are also at stake as more pressure comes from consumers, investors, and other stakeholders for companies to sell and produce sustainable products. Most importantly, we all share the responsibility of doing our part to take care of our planet in the best ways possible.

Whether you need to make a start at incorporating energy-efficient practices into your greenhouse environmental management program or want ideas to build onto what you are already doing, consider these seven strategies for maximizing energy efficiency.

1. Keep Up with Maintenance

Don’t heat the outdoors. It goes without saying that taking measures to tighten up your greenhouse envelope by patching holes, gaps, and cracks is a good place to start reducing heat loss, which can lead to higher energy costs. Doorways, fan housing, vents, low areas, and corners are common spots where air seepage can occur.

Keep in mind that air seepage can interfere with proper air circulation and ventilation in some greenhouses, so keeping up with these maintenance tasks helps you maintain an optimal growing environment. It is a good idea to add a couple of routine heat loss inspections, particularly a pre-winter one, to your greenhouse maintenance checklist as part of your overall greenhouse environmental management plan.

Anywhere you have something that exposes your greenhouse to the outside is a potential spot to reduce heat loss. Make it a habit to keep walk-through, overhead, and roll-up doors weatherproofed and shut when not in use. Check roof and wall vents to make sure they close properly and seal tightly, and repair any holes in your glazing.

2. Give Your Fans Some Love

Fans can use a lot of electricity, so don’t make them work harder than they need to. Dirt accumulation on fan blades and fan motors can throw off their performance, reducing their effectiveness and ability to keep air flowing properly. Develop a plan to clean them regularly, and while you are at it, check for bent or broken louvers that don’t close properly, and watch for anything that might block airflow, such as the wrong type of insect screening or hanging baskets.

Keep in mind also that it may be time to upgrade your fans for newer models with high-efficiency motors and higher ventilating efficiency ratios (VER). VER is a measure of cubic feet of air moved per minute per watt of input energy.

According to the Agricultural and Biological Engineering, University of Illinois at Urbana-Champaign website, efficiencies of commercially available fans typically vary by a factor of 2. The annual cost of operating the most efficient 36-inch fans for 120 days at $0.10 kWh electricity rate is about $150 compared to about $300 for the most inefficient fan. This translates to $1,500 difference in electricity costs over 10 years.

3. Harness Thermal Energy with a Water-Buffer Tank

If you use a boiler system to produce and distribute CO2 during the day, you can take things a step further with the addition of a well-insulated water buffer tank, which can help lower your energy consumption and reduce the need for natural gas to power your boilers.

Water-buffer tanks store thermal energy in the form of hot water heated by the boiler. When you have a demand for CO2 (typically during the day when you don’t have heat demand), a water-buffer tank allows you to make use of the heat produced by the boilers, instead of wasting it, to store thermal energy for use when there is heat demand.

Water from the buffer tank is distributed through a network of pipes or a hydronic heating system to evenly disperse the heat throughout the growing area, ensuring you have consistent and optimal temperatures for your crops, even when the boiler is not actively heating water.

Water tanks also help reduce boiler cycling to extend the life of your boiler, and they act as a reliable backup heat source in case of boiler failure or maintenance.

4. Minimize Boiler Usage With a CO2 Collection System

Growers providing supplementary CO2 to their plants have the challenge of how to do it without wearing down their boilers and driving up operating costs. Prospiant designs every greenhouse with a fully equipped, customized CO2 collection system that attaches directly to the CO2 condenser affixed to the natural gas boiler.

Even when you have multiple boilers, you only need to run one to produce CO2. Our CO2 collectors act as a manifold that several CO2 fans can pull from simultaneously and distribute CO2 to your greenhouse crops to increase growth rates and prevent excess CO2 from being released into the atmosphere. In seasons when your range has low heating requirements, the supplementary CO2 can help you save on natural and operating gas without needing to run all your boilers.

5. Hang Curtains to Reduce Heat Loss

When heat escapes through your greenhouse roof during the winter, heating costs tend to rise. You can use greenhouse curtain systems, also known as screens or energy curtains, on both the roof and walls of a greenhouse range. They are especially pertinent to glass greenhouses. Curtain systems are multi-purpose for heat retention, shade, light diffusion, light restriction, or blackout. The proper use of a greenhouse curtain can assist in temperature, spreading light, humidity, and trapping light.

With the right curtain system, you can gain up to 50% energy savings and maintain the best possible light and heating conditions without the need to run your boilers. Additionally, greenhouse curtains used for shading help reduce cooling costs by lowering greenhouse temperatures in the summer months. Adding multiple curtains or cavity screens can enhance energy savings and shading levels to an even greater degree.

A cavity screening system consists of two screens that operate on the same drive installation, with a narrow gap, or cavity, between them. This design leverages the insulating properties of the trapped air pocket between the screens to deliver energy savings comparable to those achieved by traditional double-screen systems that require two drive systems. Prospiant can retrofit a greenhouse with a cavity screening system using its existing drive system or install it in a new structure. The process takes an average of three weeks, depending on the scope of the project, the structures involved, and grower requirements.

With the many different types and capabilities of greenhouse curtain systems on the market today, it is important to choose the right system for your climate and the crops you grow. Our experts at Prospiant can recommend a solution that will fit the needs of your crop or climate.

6. Optimize Temperature Distribution with Air Baffles

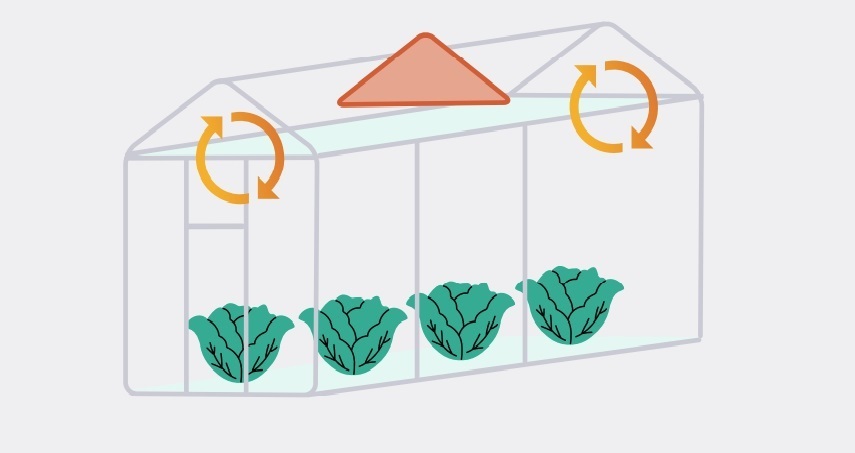

In a typical greenhouse, there is a circular airflow that contributes to a horizontal temperature gradient. Crop uniformity challenges occur when circular airflow results in the formation of heat sinks in the center of the greenhouse and cold pockets of air at the edges and corners. Growers may resort to running their boilers or using vents and fans to resolve the problem.

A more sustainable solution that saves energy and natural gas usage is to install air baffles, or triangular vertical screens, in the peaks of the greenhouse to alleviate the temperature variations. With air baffles, the air circulating above the screen doesn’t vary in temperature as greatly before falling on your plants, thus producing a more even and controlled climate for optimal crop growth.

7. Structure to Save Energy

Give thought to the impact greenhouse type, shape, orientation, and glazing materials have on energy consumption when undertaking new greenhouse construction. The type and shape of your structure determines how much surface area you will need to heat. In the past, a theory floated around that shorter greenhouses were cheaper to heat. However, consider that taller sidewall heights mean better ventilation and more air volume. The height gives warm air a place to go and acts as a climate buffer to the crop, helping to reduce temperature fluctuations.

Gutter-connected structures will typically lose less heat than freestanding greenhouses spread out over the same acreage, and greenhouse orientation needs to take advantage of winter sunlight for more aid from Mother Nature to keep the houses warm. When considering coverings, factor light transmission, heat loss rates, and thermal transmission into your decision.

Finally, seek the help of an experienced commercial greenhouse designer who understands the intricacies of greenhouse construction and equipment integration for optimal energy efficiency. Prospiant is your one-stop shop for all things commercial greenhouse, with services ranging from designing and engineering to construction and systems integration.

Greenhouse Environmental Management Has Long-Lasting Bottom-Line Benefits

Increasing production profitability requires growers to give greater importance to sustainability and opt for energy-efficient, environmentally sound growing methods. A greenhouse environmental plan is a key roadmap to helping your company improve its energy efficiency and environmental sustainability.

The complexity of sustainable greenhouse growing will only continue as we enter a new age of agtech development. Increasing your greenhouse crop yield, producing energy savings, and generating greater production efficiency is a reality with Prospiant. With more than 1,000 acres of large-scale produce projects built, our team of experts is ready to guide you through every aspect of your journey to sustainable growing.

Excerpts of this article were taken from our “5 Sustainable Ways to Increase Greenhouse Efficiency, Mitigate Risks, and Save Costs” whitepaper. Check out the whitepaper in full detail for more information on finding ways to reduce your energy footprint.

Check out some of the great greenhouse projects Prospiant has completed: