Table of Contents:

- How to Grow Cannabis 101: An Introduction to Cultivation

- Cannabis Greenhouse vs. Indoor Grow

- Minimizing Indoor Grow Costs

- How to Maximize Cannabis Yields

- Cannabis Greenhouse Construction Process

- Cannabis Cultivation Equipment

- Planning a Cannabis Cultivation Facility

- The Unique Challenges of Cannabis Cultivation

- VPD Dehumidification & Cannabis Cultivation

- Light and PAR

- Cannabis Irrigation

- Top 20 Cannabis Growing Questions – FAQ

- Glossary of Terms: Cannabis and Hemp Extraction

- Industry Resources

VPD Dehumidification & Cannabis Cultivation

What is Vapor Pressure Deficit (VPD) Cannabis Dehumidification?

Vapor pressure deficit (VPD) is the difference between the moisture (water) in the air versus how much water the air can hold in total. When your goal is to produce a quality cannabis crop, VPD dehumidification is a critical factor in your growing SOP (standard operating procedure) because it’s essentially the shortcut to ensuring your cannabis will grow at just the right humidity levels.

VPD measures your humidity levels in a greenhouse or indoor grow facility to keep them in the ‘sweet spot’. VPD allows us to gauge the impact of humidity on plant growth to ensure optimum moisture levels. The interaction of VPD and HVAC systems is absolutely critical in cannabis cultivation because they directly impact how well your cannabis plants will grow and thrive.

VPD also measures the transpiration of moisture given off by your cannabis plants so you can track transpiration levels and monitor VPD to ensure a successful crop.

Table of Contents:

1. The Benefits of VPD for Cannabis Dehumidification

3. What is the VPD Psychrometric Chart and how does it work?

4. What is the relationship between VPD and RH (relative humidity)?

5. Dehumidification differences by climate

6. How does VPD help high humidity levels?

7. Dehumidification Technologies

8. What equipment do I need to control temperatures and humidity?

The Benefits of VPD for Cannabis Dehumidification

Why are we concerned about VPD levels in your cannabis grow facility? To answer this question we need to look at how the plant ‘breathes’ and how it gives off moisture. The measurement of VPD delivers the following benefits that will positively impact your crop.

As the cannabis or hemp plant grows, its transpiration process (exhalation of water) occurs through the stomata, the cells located on the leaf surface. The plant releases water vapor through these stomata, increasing humidity in a greenhouse or indoor grow facility. When you have an optimal VPD, your cannabis plant opens its stomata more. Therefore, there is more water vapor in the room and more water vapor means increased transpiration.

As the plant’s stomata open up wider, faster transpiration leads to an increase in photosynthesis activity, nutrient uptake, and plant growth. The ability to monitor and control VPD allows you to manage a plant’s nutrient and water intake. Optimal VPD will let cannabis transpire water faster to pull in more nutrients and increase growth.

In order to photosynthesize properly, cannabis plants need to absorb the correct amount of CO2. VPD also makes it easier to control CO2 uptake. With ideal VPD levels, the stomata can open wider and take in more CO2.

How is VPD Calculated?

The calculation of VPD in your greenhouse or indoor grow is not as complicated as it sounds. You need the following measurements:

- Indoor temperature

- Relative humidity (RH)

- Saturated vapor pressure values for your local climate.

The following formula will enable you to calculate your VPD:

- VPD = ((100-RH/100) x SVP)

The results of this formula are measured in Pascals, which are then converted into Hectopascals by dividing by 100.

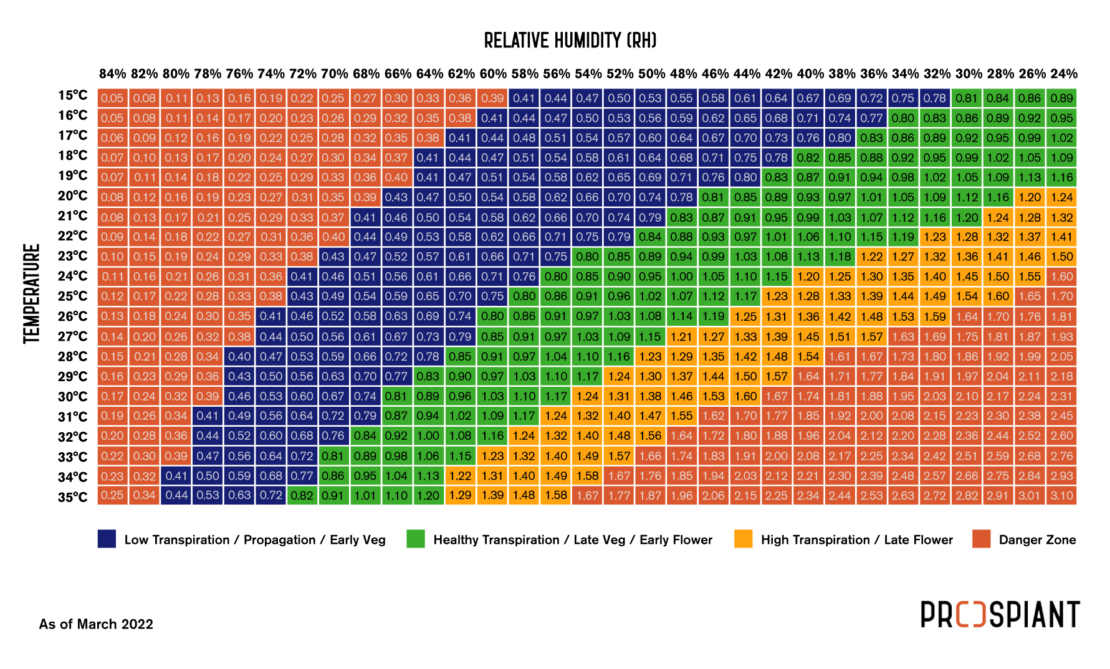

When you get your final answer, locate it on the following chart to ascertain if you are in the ideal range for optimum cannabis growth.

What is the Cannabis VPD Psychrometric Chart and how does it work?

The VPD cannabis chart is a handy tool that will directly impact the performance of your cannabis cultivation operation. The chart centers around the three factors mentioned above: temperature, relative humidity, and VPD. With the correct levels of each of these three critical factors, you can maximize growth easily.

The temperature in your greenhouse or indoor grow facility is important because it impacts the amount of water the air can hold. Relative humidity (RH) determines the amount of water vapor contained in the air. Knowing your target VPD range will give you the flexibility to achieve various combinations of temperatures and humidity to not only grow a healthy crop but also to maximize energy savings.

The VPD chart helps you to ascertain the relationship between temperature and relative humidity, which informs on the ideal VPD parameters during the various critical plant growth stages.

To maximize cannabis growth, you want your VPD to fall within the specified ranges at each phase of the plant lifecycle. Within these ranges, your plants should be able to develop normally and grow well.

For example, at propagation, the plant is sensitive to any stresses, and thus VPD should remain on the lower end of the spectrum. As the plant grows, the VPD ranges can increase, culminating in recommended ranges of 0.96 to 1.15 k/Pa during flowering. Some growers prefer to enter the plants into even higher VPD ranges at this stage, to stress the plant before harvest.

The red areas on the chart denote a negative relationship between temperature and relative moisture. On the left side, VPD is too low, prohibiting the plant from releasing enough water, and impacting its ability to photosynthesize properly. On the red areas on the right side, VPD is too high, meaning the plant will transpire faster than it can replace the water, leading to tissue damage, wilting, and a failed crop.

What is the relationship between VPD and RH (relative humidity)?

Most growers would traditionally use RH to measure greenhouse or indoor humidity but in recent years, VPD is becoming more popular because it’s a more accurate form of measurement and produces better crops.

VPD is more focused on the overall health of your plants and allows you to better optimize the correct bandwidth of humidity for cannabis plants. This optimization results in larger yields, improved quality, and optimum plant growth.

RH only measures how saturated the air is with moisture. VPD measures the difference between moisture saturation and the existing amount of moisture in the air, in terms of pressure.

The way this works in practice is that higher VPD levels mean that more water can be held in the air before condensation occurs, especially ideal for an environment where the relative humidity is low. And conversely, lower VPD levels are evident in an environment where less moisture can be held in air before condensation occurs.

Cannabis Dehumidification differences by climate

Depending on the physical geolocation of your cannabis greenhouse or indoor grow, your relative humidity (RH) levels will differ. It’s critical that you understand your local climate’s RH to enable you to optimize the humidity levels inside your facility.

In hot, high-humidity climates such as the tropics (the regions of Earth surrounding the Equator) your cannabis greenhouse may need extra dehumidification systems to ensure that levels are kept in the ideal range for optimum crop growth.

If your humidity levels are too high your plants cannot cool themselves via transpiration. If the plants don’t release water they also stop taking it from the roots, resulting in nutrient intake slowing down and decreasing plant growth. This is the ‘danger zone’ and your entire crop is at risk from mold spores and powdery mildew causing ‘bud rot’ leading to crop (and revenue!) loss.

In dry climates, such as the high desert, your cannabis greenhouse may in fact need additional moisture added into the air via ’wet walls’ or other humidifying equipment.

How does VPD help high humidity levels?

If your humidity level is too high, in the best-case scenario, your yield will be significantly reduced. In the worst-case scenario, mold will breed quickly—especially during the flowering stage—leading to a ruined crop.

VPD helps you track the cannabis plants’ release of moisture, AKA transpiration. It’s a natural process that plants undertake throughout the day to cool themselves but results in humidity levels going up in your greenhouse or indoor grow facility. As the plants release moisture they need to uptake more water. If this endless cycling of H2O is not monitored effectively your humidity levels can go out of control pretty quickly.

Awareness of how irrigation, transpiration, and humidity works in your growing space will help you avoid these pitfalls. Ultimately, the real solution to this challenge is the computerized automation of your growing equipment and environmental technologies and processes so you can track these levels at night or at other times when your grow may not be supervised by humans.

Dehumidification Technologies

There is a range of technologies available for a greenhouse, hybrid, or indoor grow cannabis-focused dehumidification.

Passive Vent

Passive dehumidification uses heat pipe technology to remove more humidity from the air than a regular HVAC system. Passive vents work via air movement over a pipe filled with cold fluid which draws heat from the air and causes condensation thus reducing the moisture in the air.

Mechanical Ventilation

Mechanical ventilation is the tried-and-true greenhouse ventilation method that uses a fan and pad mechanical ventilation system. This system will exhaust the hot greenhouse air through inlets and provide a cooler environment by pulling air through a wet wall.

It works by using fans to exchange air with the outside of the facility. Fans deliver predictable amounts of air exchange and consistent airflow direction. They can either push air into the greenhouse (positive displacement), or they can pull air out of the greenhouse (negative displacement). Fan size is typically determined based on maximum cooling requirements and minimum ventilation requirements (for CO2 replenishment and/or moisture removal).

Learn more about Mechanical Ventilation.

Commercial Dehumidifiers

Commercial or industrial dehumidifiers are appliances that reduce the level of humidity. Commercial dehumidifiers can remove between ~150-250 pints of moisture from the air per day and are ideal for high-humidity climates.

However, the one drawback with commercial dehumidifiers is that they blow warm air out of the back of the unit. In the winter, this means your unit will double as a heater but in a hot humid climate (think Florida or Hawaii) they’ll heat up your space. You may need to position the dehumidifier near an external doorway so that it doesn’t heat up the space from which you are removing excess humidity.

Four Pipe

The Four Pipe system contains both a hot water supply with return lines and a chilled water supply with return lines. The two supply and two return pipes for both heating and cooling allow for simultaneous heating and cooling of your indoor grow space which also allows for dehumidification.

Desiccant

Desiccant dehumidifiers absorb moisture from the air into desiccant materials. They work by using a large desiccant ‘wheel’ to absorb moisture from an air stream. As the air is dried, the moisture content of the wheel rises. The wheel is in constant rotation to dispel the moisture as a second air stream is passed through the wheel.

What equipment do I need to control temperatures and humidity in cannabis greenhouses and indoor grow facilities?

Selecting high-quality greenhouse equipment can help you better control the temperature and humidity within your greenhouse or indoor growing facility, leading to higher yields and more predictable results.

HVAC (Heating, Ventilation, and Air Conditioning) Systems

A high-quality HVAC system is possibly the most important ingredient of your greenhouse or indoor grow facility. It controls temperature and humidity which are critical components to achieving your optimal VPD.

The cost of energy is always going up, so when considering the energy costs associated with indoor grow environments, proper HVAC systems will not only give you proper environmental control but it can do so with significant energy and cost savings.

Fans

Extractor fans can pull the hot air out of your greenhouse or indoor grow facility, replacing it with fresh, cool air. Fans are the traditional way to regulate airflow and are best placed near the top of the room because hot air rises.

Grow Lighting

Grow lights are ideal for greenhouses or indoor grow warehouses to enhance plant production by providing additional light control to your crop. The newer LED grow lights will ensure that your plants get the light source they need without excessive heat. Typically, a minimum range of 32 watts per plant is recommended.

When it comes to the most cost-savvy lighting solution LED lights, although more expensive at first, can offer significant energy savings over their life cycle, compared to traditional High-Pressure Sodium lights.

Environmental Controls

To automate the running of all of the equipment mentioned above, it pays to seamlessly integrate and automate all environmental control systems so that they’re running in sync and harmoniously with each other. You will save time and money and decrease business risk due to human error.

To properly utilize all the equipment in your greenhouse an environmental control system is essential. These systems can be very simple thermostats or as sophisticated of a computer control as you can imagine.

With the setting of parameters decided on by you these controls can efficiently cycle your equipment through their stages to achieve the environment you want.

Top benefits of automated environmental controls:

- Most are user-friendly with simple-to-operate automation

- You can set parameters to your unique needs

- Use easily replicable programming to run all equipment

- Automate watering, temperatures, humidity, etc.

- Multi-zone capabilities that help you make the most of your space

Learn more about greenhouse and indoor grow environmental controls here.